Yttrium oxide ceramic powder, commonly known as Y₂O₃, is a high-purity, fine ceramic material widely used in various industrial applications. Known for its excellent thermal stability, high melting point, and strong resistance to corrosion, it is ideal for use in high-temperature environments. Yttrium oxide is often used in the production of advanced ceramics, coatings for semiconductor components, and optical materials due to its outstanding optical transparency and mechanical strength. Additionally, it serves as a critical material in the manufacturing of phosphors for color TV tubes, LED displays, and other electronic devices. Our Yttrium oxide ceramic powder is available in various particle sizes to meet the specific needs of your production processes, ensuring superior performance and reliability.

| Type | Chemistry(wt%) | Hardness | Typical Application | |||||||||

| Y2O3 | Fe2O3 | Al2O3 | CaO | SiO2 | MgO | TiO2 | ||||||

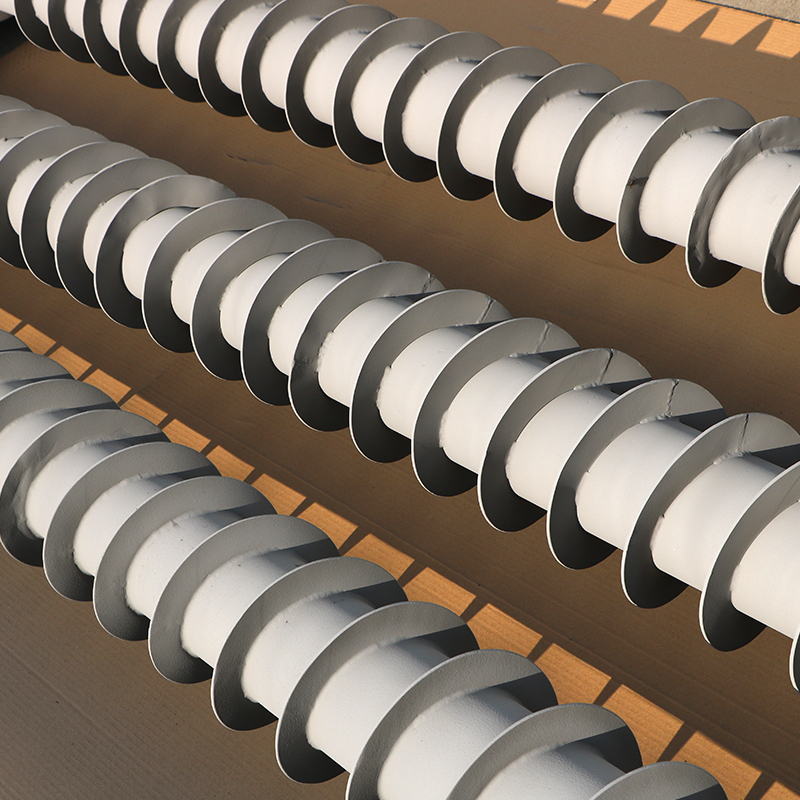

| Y2O3 (semiconductor industry) | 99.99% | <0.1% | <0.1% | <0.1% | <0.1% | / | / | 350-450HVo.3 | Recommended for use in the semiconductor industry and liquid crystal display (LCD) components, electrostatic chucks, vacuum chamber walls, fuel cells, engine components, precision components sintered boat dish protective layer and special industries. | |||

| Y2O3 (graphite boat industry) | 99.99% | <0.1% | <0.1% | <0.1% | <0.1% | / | / | 350-450HVo.3 | Recommended applications include graphite protective coatings in the cemented carbide industry, graphite molds, fuel cells, engine components, sintered boat protective layers for precision components, and special industries. | |||

| ZrO2-8Y2O3 | ~7.5-8% | / | / | / | <0.1% | <0.1% | <0.1% | 600HVo.3 | Recommended for aerospace, power generation gas turbine blades, combustion section components, transition section arrow nozzles, cylinder heads, jet engine combustion chambers, intake valves, combustion liners, turbochargers, and other parts suitable for thermal barrier coatings that increase porosity. | |||

| ZrO2-20Y2O3 | ~18-22% | / | / | / | <0.1% | <0.1% | <0.1% | / | Graphite protective coatings in the cemented carbide industry, graphite molds, diesel engines, heat treatment equipment, aerospace parts, industrial gas turbine parts, missile nose cones, rocket nozzles, and other heat-resistant parts of the heat-insulating coatings. | |||

English

English русский

русский عربى

عربى