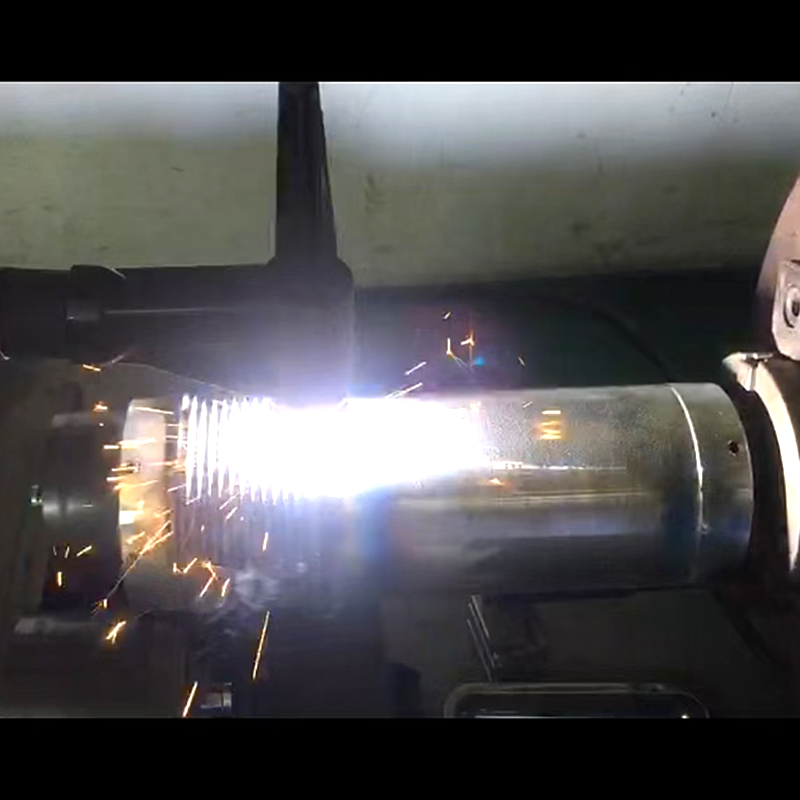

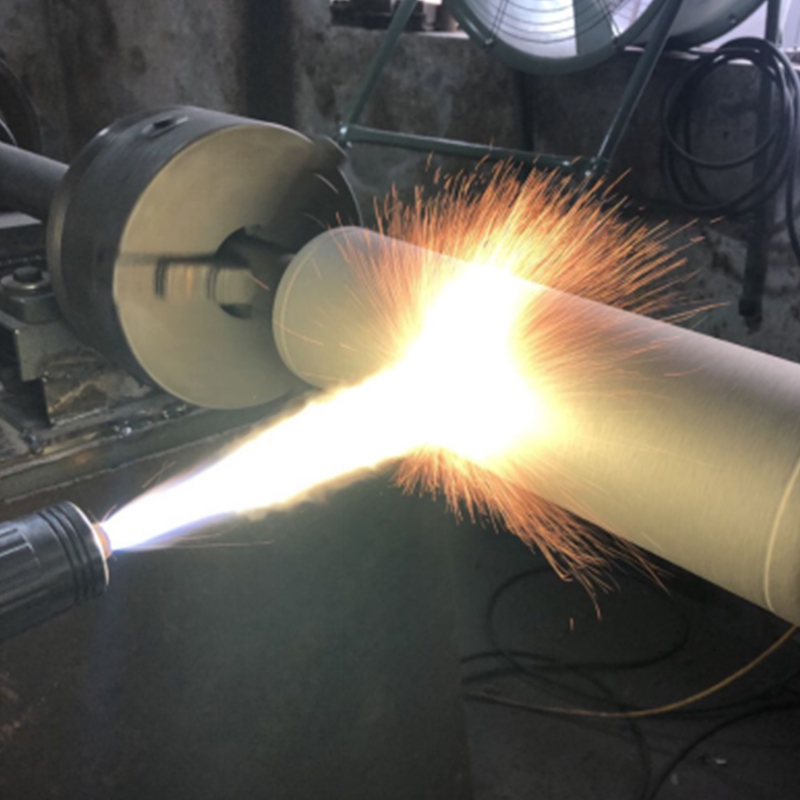

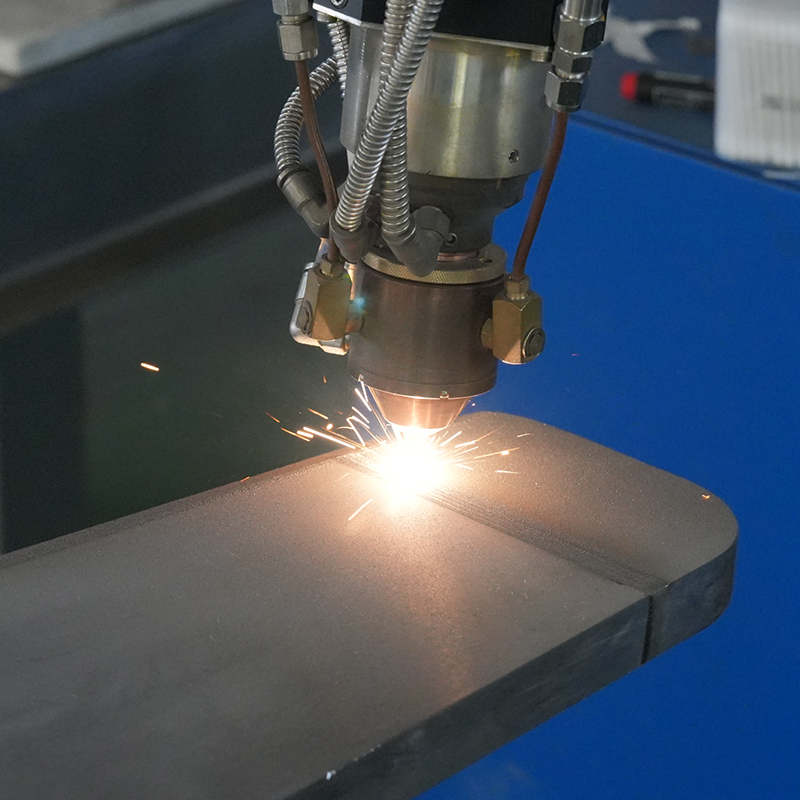

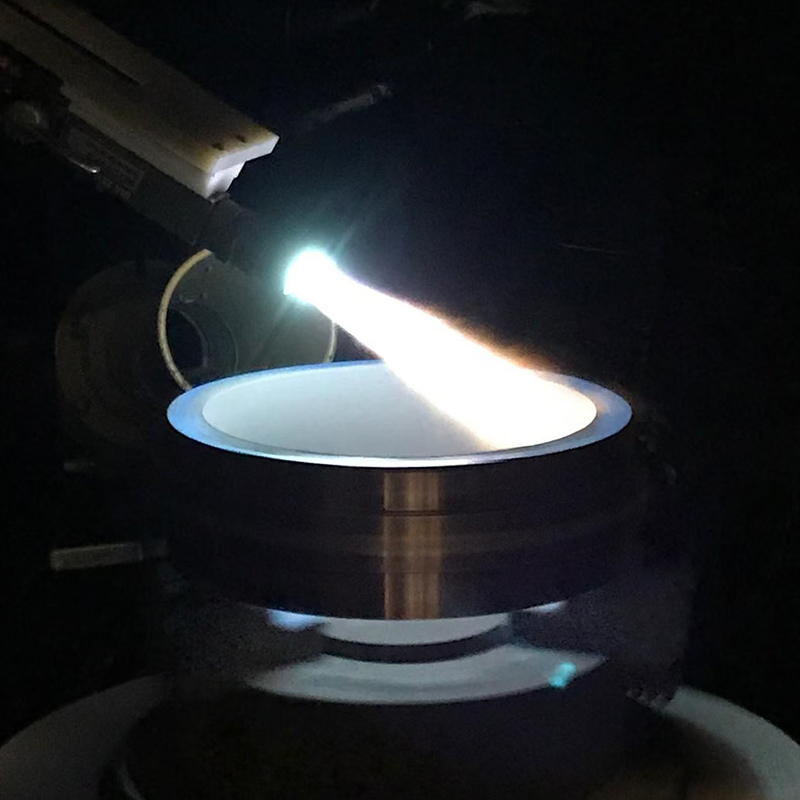

The plasma powder surfacing process uses a water-cooled copper nozzle to compress the arc column of the free arc, so that the energy is more concentrated and the gas in the arc column is fully ionized. Such an arc is called a plasma arc. The energy of the plasma arc is highly concentrated, and the temperature reaches an extremely high level (about 10,000 to 20,000 degrees Celsius). The high temperature generated rapidly heats and melts the alloy powder and the surface of the substrate together, forming a high-quality alloy welding layer on the surface of the substrate.

The plasma powder cladding welding process is accepted by more and more customers due to its low weld layer dilution rate, small impact on the substrate, easy automation, and high quality reproducibility. It has been successfully used in automobiles, electric power, petrochemicals, etc. many areas.

English

English русский

русский عربى

عربى