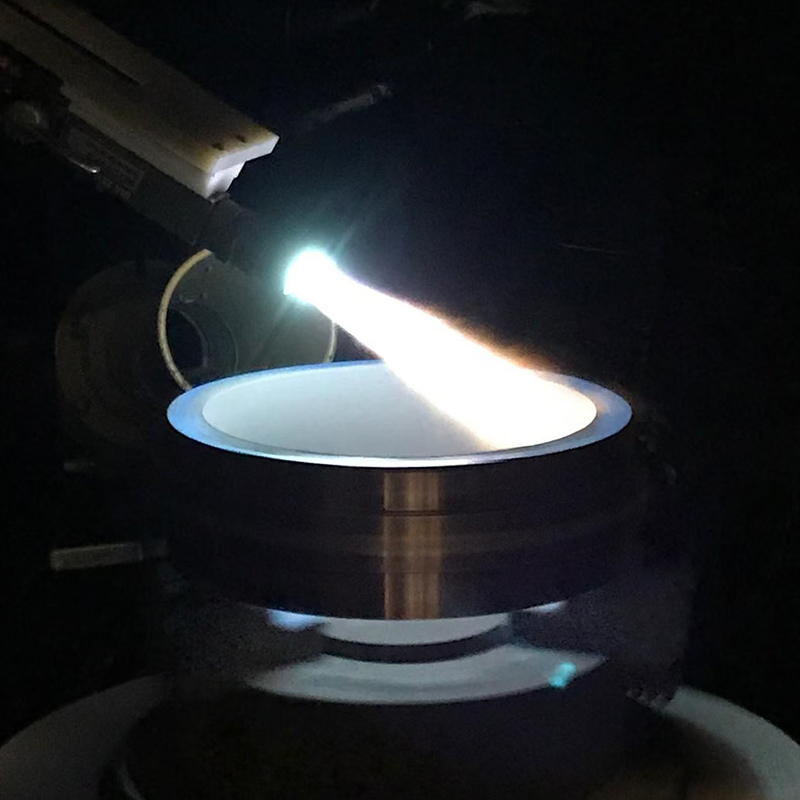

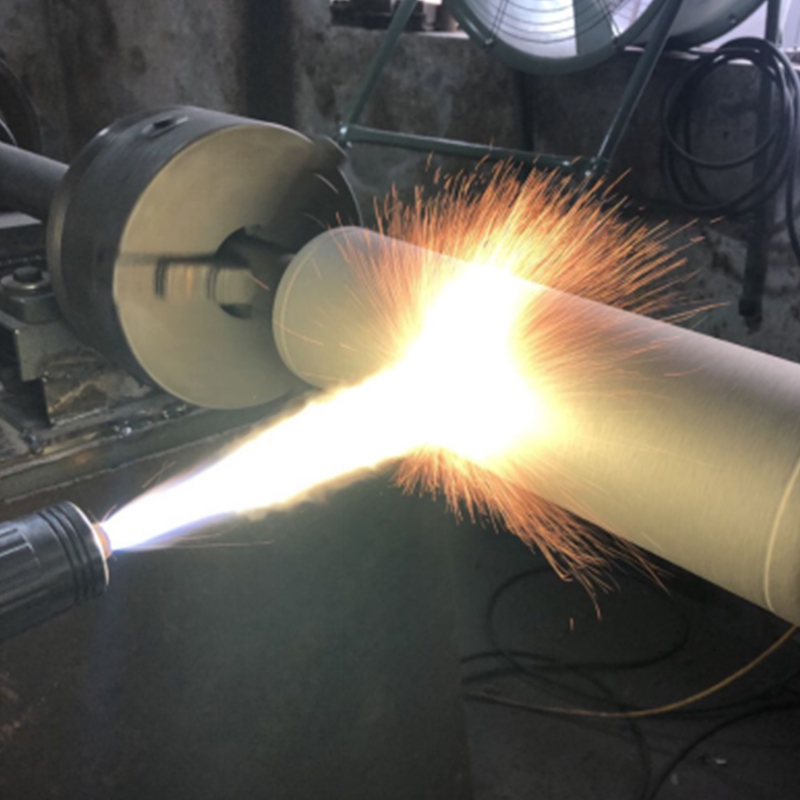

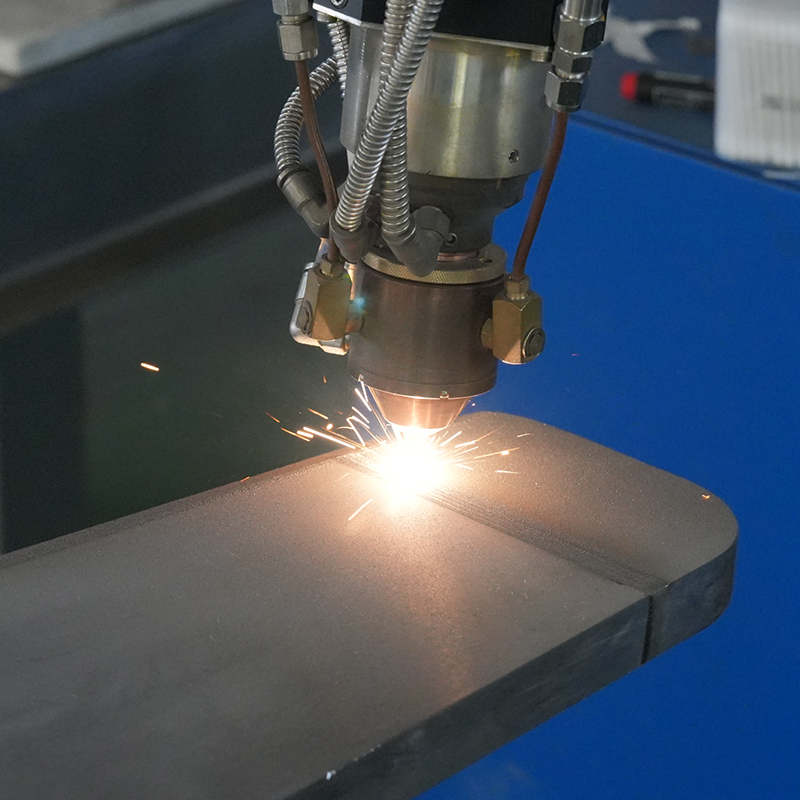

Plasma spraying is a material surface strengthening and surface modification technology, that can make the surface of the substrate with wear-resistant, corrosion-resistant, high-temperature oxidation-resistant, electrically insulating, heat-insulating, radiation-resistant, abrasion-reducing, and sealing properties. Plasma spraying technology is the use of a DC-driven plasma arc as a heat source, ceramics, alloys, metals, and other materials heated to a molten or semi-molten state, and sprayed at high speeds to the surface of the pre-treated workpiece and the formation of a solidly adhered to the surface layer of the method. Plasma spraying is also used in medical applications, where a coating of tens of microns is sprayed on the surface of artificial bones as a way to strengthen them and enhance their affinity.

Plasma spraying is a new multi-purpose precision coating method developed after flame spraying. It has the following features: ① Ultra-high-temperature characteristics, which facilitates the coating of high melting point materials. ② high speed of spray particles, dense coating, high bonding strength. (iii) Since inert gas is used as the working gas, the sprayed material is not easy to oxidise.

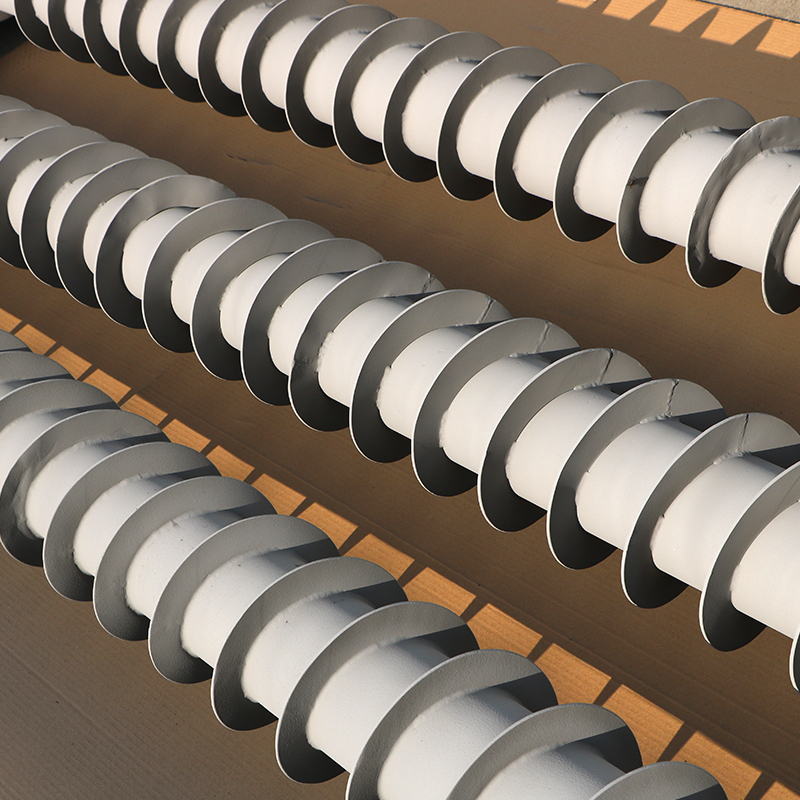

Plasma Ceramic Coating

Powder, (can be customized pure nickel powder, pure cobalt powder, pure copper powder, etc.) metal powder.

We are always committed to developing and producing various high-performance alloy materials for harsh environments, providing customers with high-strength, wear-resistant, corrosion-resistant and high-temperature-resistant alloy powders.

News

-

Industry News 2025-12-24

Advanced Classifications of Copper-Based Alloy Powders Copper-based alloy powders are engineered materials characterized by their high thermal and electrical conductivity, combined with enhanced mechanical properties tai...

View More -

Industry News 2025-12-16

Beyond the Bar: Understanding Cobalt Alloys Cobalt, a hard, lustrous, silver-gray metal, is more than just a component in lithium-ion batteries. When alloyed with other elements like chromium, tungsten, molybdenum, or ni...

View More -

Industry News 2025-12-09

The Global Quest for Extreme Durability In the world of manufacturing, mining, and aerospace, nothing is more valuable than durability. Every time a drill bit snaps, a turbine blade erodes, or a bearing wears out, it cos...

View More

English

English русский

русский عربى

عربى