Nickel-based alloys are based on nickel and are usually supplemented with chromium, carbon, boron, iron and silicon. They cover a wide range of hardnesses, from soft to hard. These alloys are easy to machine or hand-grind, and can be converted into cemented carbides with extremely high wear resistance. Depending on the application, the hardness of the alloy can be selected between 20 and 62 HRC.

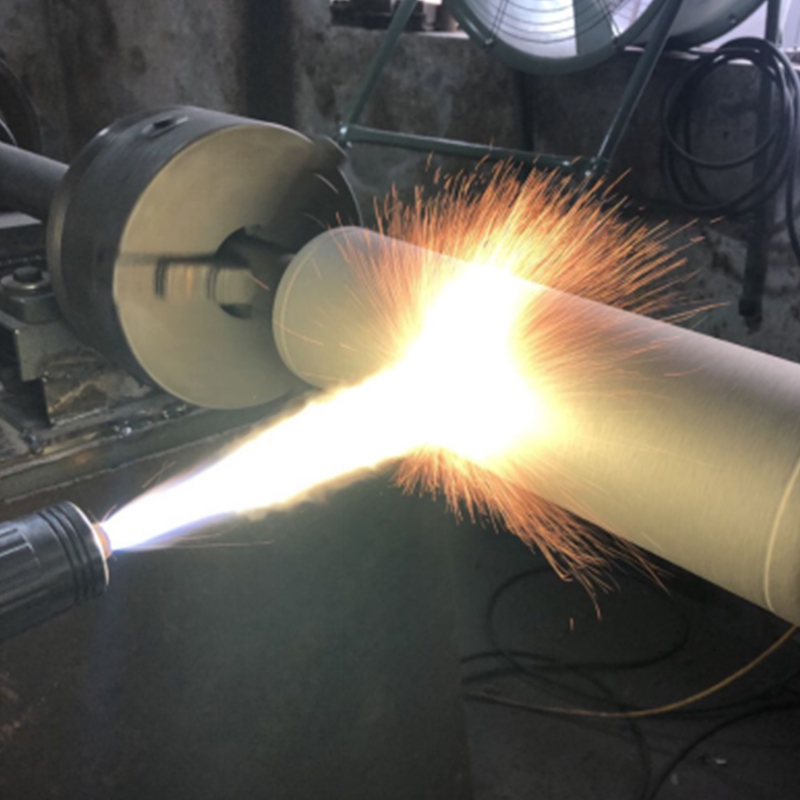

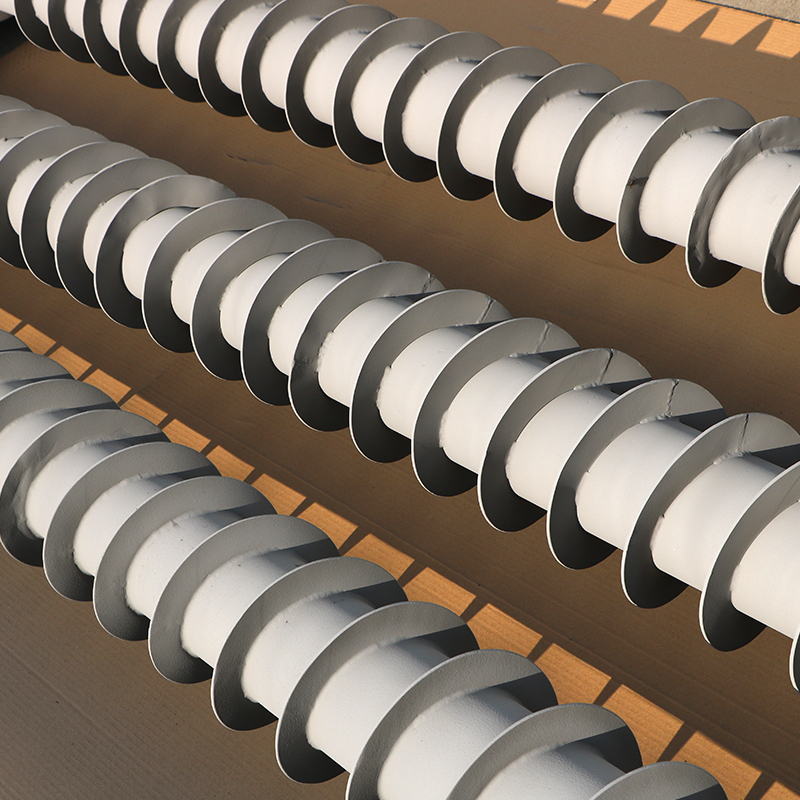

The lower hardness alloys are often used in glass forming molds, while the higher hardness alloys are suitable for severe wear applications, such as repairing the helical wings of feed screws. By mixing with carbides, they can also form a harder surface deposit. These alloys can maintain good performance at temperatures up to 315°C (600°F) and have good oxidation resistance.

| Type | HRC | Chemistry(wt%) | Typical Application | |||||||||

| C | Cr | Si | W | Fe | Mo | Ni | Co | Mn | B | |||

| SD-Ni25 | 25 | 0.2 | 3.5 | 8 | Bal | 1.5 | Glass mold, various forming dies | |||||

| SD-Ni35 | 35 | 0.3 | 10.5 | 3.5 | 10 | Bal | 2 | Glass mold, various forming dies | ||||

| SD-Ni45 | 45 | 0.45 | 12 | 4 | 10 | Bal | 0.1 | 2.4 | Exhaust valve seat, plunger | |||

| SD-Ni55 | 55 | 0.75 | 15.5 | 4 | 14 | 3 | Bal | 3 | Molds, can, plunger, and exhaust valve | |||

| SD-Ni60 | 59 | 0.8 | 15.5 | 4 | 15 | Bal | 3.5 | Plunger, drawing rollers, can, mechanical, wear, parts | ||||

| SD-Ni60 B | 58 | 0.6 | 17 | 3 | 20 | Bal | 4 | Valve plates, etc., mechanical wear parts | ||||

| SD-Ni6O M | 60 | 0.8 | 17 | 4 | 15 | Bal | 3.2 | Laminar flow rollers, drawing rollers, mechanical wear parts | ||||

| SD-Ni6OJH3 | 60 | 0.8 | 16 | 4 | 10 | Bal | 3.5 | Valve plates, plungers, mechanical wear parts | ||||

| SD-Ni62 | 61 | 1 | 15.5 | 3.8 | 10.5 | 14 | Bal | 4 | Paper brake wheel, shovel teeth | |||

| SD-Ni65 | 62 | 0.8 | 16 | 4 | 5 | 15 | Bal | 3.2 | Screw feeders, plungers, mechanical wear parts | |||

| SD-Ni220M1 | 26 | 0.05 | 4 | 3 | 3 | 0.05 | 0.5 | 1 | Powder for plasma welding glass moulds | |||

| SD-NiB | Cold and Hard | 0.1 | 1 | 1 | V: 0.30 | 5 | 28 | Bal | 2.5 | Sealing ring for high temperature and corrosion resistance | ||

| SD-Ni820 | 20 | 0.03 | 4.5 | 2 | Bal | 0.7 | Glass mold, various forming die | |||||

| SD-Ni822 | 22 | 0.2 | 0.1 | 2.85 | 0.5 | Bal | 0.5 | 1.45 | Glass mold, various forming die | |||

| SD-Ni822M2 | 22 | 0.05 | 3 | 2.3 | Bal | 0.8 | Glass mold, various forming die | |||||

| SD-Ni828 | 28 | 0.05 | 0.1 | 2.8 | Bal | 1 | Glass mold, various forming die | |||||

| SD-Ni830 | 30 | 0.15 | 2.5 | 2.6 | 1 | Bal | 0.3 | 1.4 | Slide rail, gear teeth | |||

| SD-Ni831M | 30 | 0.05 | 3.5 | 3 | 3 | Bal | 0.4 | 1 | Glass fixtures with full spray welding | |||

| SD-Ni835 | 35 | 0.2 | 4 | 3.2 | 1.4 | 0.1 | Bal | 0.1 | 1.6 | Glass molds, valve seat | ||

| SD-Ni837 | 36 | 0.15 | 4.5 | 2.6 | Bal | 1 | Glass mold, various forming die | |||||

| SD-Ni840 | 40 | 0.3 | 7.5 | 3.5 | 2.3 | 0.1 | Bal | 0.1 | 1.7 | Screw feeder, die inserts, etc | ||

| SD-Ni843 | 40 | 0.2 | 5 | 3 | 0.5 | 3 | Bal | 0.5 | 1 | Glass mould punch | ||

| SD-Ni850 | 50 | 0.4 | 11 | 4 | 2.7 | 0.1 | Bal | 0.1 | 2.2 | Pump shaft, pulp knives, valve, screw rod | ||

| SD-Ni855S | 52 | 1 | 18 | 5 | 3 | 5 | Bal | 1.8 | Screw, Seat | |||

| SD-Ni860 | 59 | 0.65 | 15 | 4.3 | 4 | 0.1 | Bal | 0.1 | 3.1 | Extrusion press, screw barrel, pump impeller, plunger, etc | ||

| SD-Ni86325 | 57 | 0.5 | 16 | 4 | Cu;3.00 | 4.5 | 3 | Bal | 0.1 | 3.5 | Corrosion resistance pump shaft, bearing sleeve | |

| SD-Ni880 | 40 | 1 | 23 | 2.5 | 1 | 3 | 7 | Bal | 1 | 1 | Valve | |

| SD-Ni8700 | 54 | 0.08 | 15.5 | 3.4 | 1.5 | 32.5 | Bal | 1.5 | Used in the nuclear industry for corrosion oxidation and radiation resistance | |||

English

English русский

русский عربى

عربى