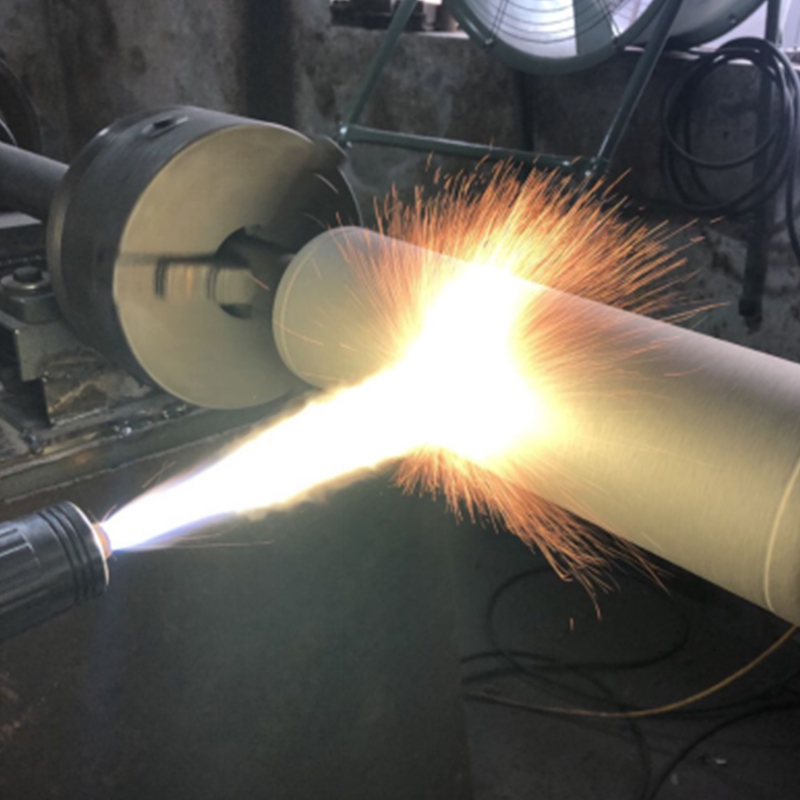

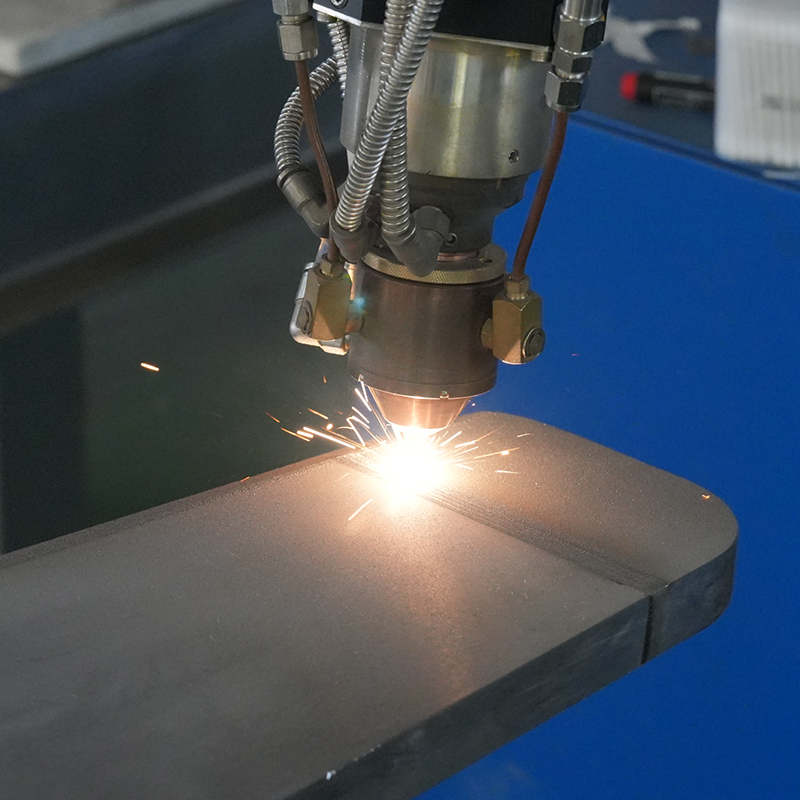

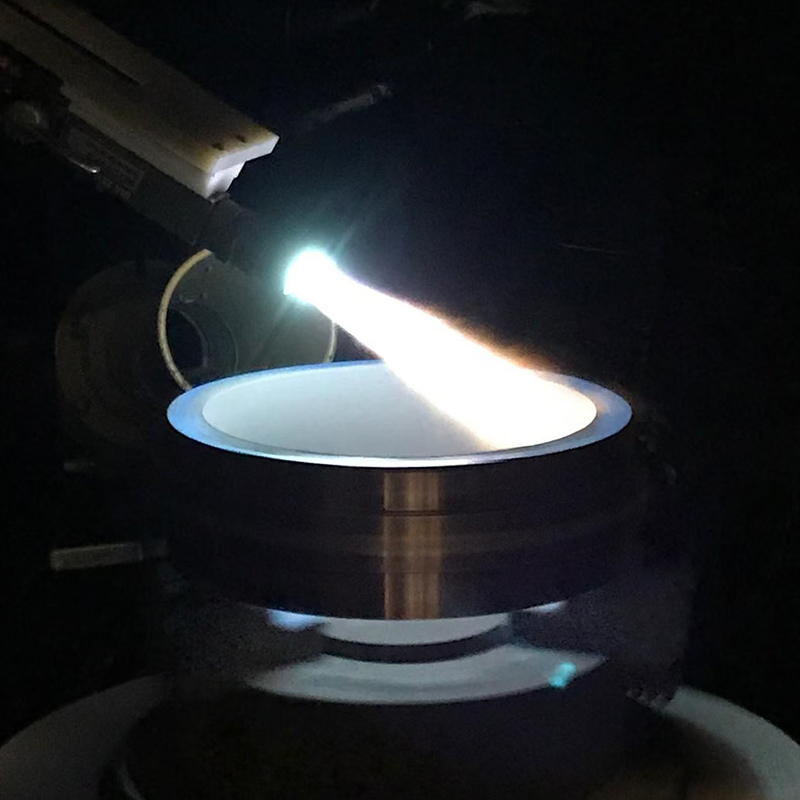

Laser cladding, also known as laser cladding or laser melting, is a new surface modification technology. It forms a filler cladding layer metallurgically bonded to the substrate surface by adding cladding material to the substrate surface and using a high-energy-density laser beam to clad it together with a thin layer on the substrate surface.

Currently, the materials commonly used for laser cladding are mainly thermal spraying or thermal spraying materials, including self-soluble alloy materials, carbide dispersion or composite materials, and ceramic materials.

With the increasing maturity of laser technology and the widespread application of high-power lasers, the laser cladding process has been gradually promoted and applied due to its advantages such as small workpiece deformation, low dilution rate, small cladding layer processing allowance, dense structure, and effective guarantee of alloy performance. However, laser cladding is very likely to cause stress cracking due to concentrated heat input. Based on the understanding of the characteristics of laser cladding technology, we have developed a series of laser cladding powders, and the product process performance and use performance have been unanimously recognized by customers.

| Powder | HRC | Chemical Composition | Mesh | ||||||||

| C | Cr | Si | W | Fe | Mo | Ni | Co | B | |||

| SD-Ni820 | _ | 0.02 | 4.5 | 3.25 | _ | 2.3 | _ | Bal | _ | 1 | 100/270mesh |

| SD-Ni825 | 25 | 0.01 | 0.4 | 3.2 | _ | 3.25 | _ | Bal | _ | 1.25 | 100/270mesh |

| SD-Ni830 | 30 | 0.1 | 18.7 | 3 | _ | 4.5 | _ | Bal | _ | 0.8 | 100/270mesh |

| SD-Ni835 | 35 | 0.25 | 7.6 | 3 | _ | 4.7 | _ | Bal | _ | 2.2 | 100/270mesh |

| SD-Ni840 | 40 | 0.3 | 12.1 | 3.65 | _ | 0.8 | _ | Bal | _ | 1.8 | 100/270mesh |

| SD-Ni845 | 45 | 0.7 | 19.1 | 5.25 | _ | 5.1 | _ | Bal | _ | 1.9 | 100/270mesh |

| Powder | HRC | Chemical Composition | Mesh | ||||||||

| C | Cr | Si | W | Fe | Mo | Ni | Co | Mn | |||

| SD-Co01 | 52 | 2.4 | 30 | 1 | 12 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | 100/270mesh |

| SD-Co06 | 42 | 1.2 | 30 | 1 | 4.5 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | 100/270mesh |

| SD-Co12 | 46 | 1.4 | 30 | 1 | 8.5 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | 100/270mesh |

| SD-Co12H | 48 | 1.6 | 30 | 1 | 8.5 | ≤3.00 | ≤1.00 | ≤3.00 | Bal | ≤1.00 | 100/270mesh |

| SD-Co21 | 25 | 0.3 | 28 | 1.2 | _ | ≤3.00 | 5.5 | ≤3.00 | Bal | ≤1.00 | 100/270mesh |

| SD-Co6H | 44 | 1.3 | 30 | 1.5 | 5.5 | 3.00Max | 0.8 | 3.0Max | Bal | 1.00Max | 100/270mesh |

| SD-Co12N | 50 | 1.3 | 29 | 0.8 | 8.5 | ≤3.00 | ≤1.00 | 11 | Bal | ≤1.00 | 100/270mesh |

| SD-CoFH | 42 | 1.4 | 28 | 1.2 | 12 | 3.00Max | 0.8 | 22.5 | Bal | 0.5 | 100/270mesh |

| Powder | HRC | Chemical Composition | Mesh | ||||||||

| C | Cr | Si | W | Fe | Mo | Ni | B | Mn | |||

| SD-JG20 | - | 0.05 | 18.5 | 1.1 | _ | Bal | 2 | 11 | 0.6 | 0.04 | 100/270mesh |

| SD-JG25 | 25 | 0.1 | 17 | 0.9 | _ | Bal | 1.3 | 6.3 | 0.7 | 0.3 | 100/270mesh |

| SD-JG30 | 30 | 0.12 | 17 | 1 | _ | Bal | _ | 5.5 | 0.7 | 0.3 | 100/270mesh |

| SD-JG35 | 35 | 0.12 | 16.9 | 1 | _ | Bal | _ | 5 | 0.7 | 0.3 | 100/270mesh |

| SD-JG40 | 40 | 0.12 | 19.8 | 1 | _ | Bal | 1.4 | 2.5 | 0.9 | 0.3 | 100/270mesh |

| SD-JG45 | 45 | 0.13 | 16.7 | 1.1 | _ | Bal | _ | 4.5 | 0.65 | 0.3 | 100/270mesh |

| SD-JG50 | 50 | 0.16 | 18.5 | 1.1 | _ | Bal | 0.5 | 2.5 | 1 | 0.6 | 100/270mesh |

| SD-JG55 | 55 | 0.18 | 18.2 | 1.1 | _ | Bal | 0.5 | 1 | 1.2 | 0.5 | 100/270mesh |

| SD-JG60 | 60 | 0.16 | 18.5 | 1.2 | _ | Bal | 0.5 | 0.8 | 1.4 | 0.5 | 100/270mesh |

| Iron-based laser powders | |||||||||||

| Type | Chemistry(wt%) | Hardness | Particle Size | Typical Application | |||||||

| C | Cr | Si | Fe | Mo | B | Ni | Others | ||||

| SD-JG-20 | 0.06 | 18 | 0.8 | Bal | 1.3 | 12 | 20 | 100/270 | Valve or casting priming | ||

| SD-JG-30 | 0.07 | 17.5 | 0.8 | Bal | 1 | 7 | 30 | 100/270 | Shaft Repair | ||

| SD-JG-45 | 0.07 | 17.5 | 1 | Bal | 2 | 0.9 | 5.5 | Mn:0.50 | 46 | 100/270 | Roll and shaft repair |

| SD-JG-50 | 0.1 | 17.5 | 1 | Bal | 2.5 | 1 | 5 | Mn:0.50 | 49 | 100/270 | Hydraulic support column |

| SD-JG-55 | 0.2 | 17.5 | 1.5 | Bal | 1 | 2 | 55 | 100/270 | Shaft Repair | ||

| SD-JG-58 | 0.25 | 18.5 | 1 | Bal | 5 | 1 | 2 | Mn:5.00 | 58 | 100/270 | Roller Repair |

| SD-JG-60 | 0.36 | 17.91 | 1.07 | Bal | 1.65 | 0.45 | 60 | 100/270 | Roll and shaft repair | ||

| SD-JG-304 | 0.07 | 18 | 0.1 | Bal | 2 | 10 | Mn:2.00 | 100/270 | Medical devices, chemicals, food industry, marine components | ||

| SD-JG-316L | 0.03 | 18 | 0.5 | Bal | 2.5 | 12 | Cu:0.20 | 100/270 | Food industry, ships | ||

| Mn:2.50 | |||||||||||

English

English русский

русский عربى

عربى