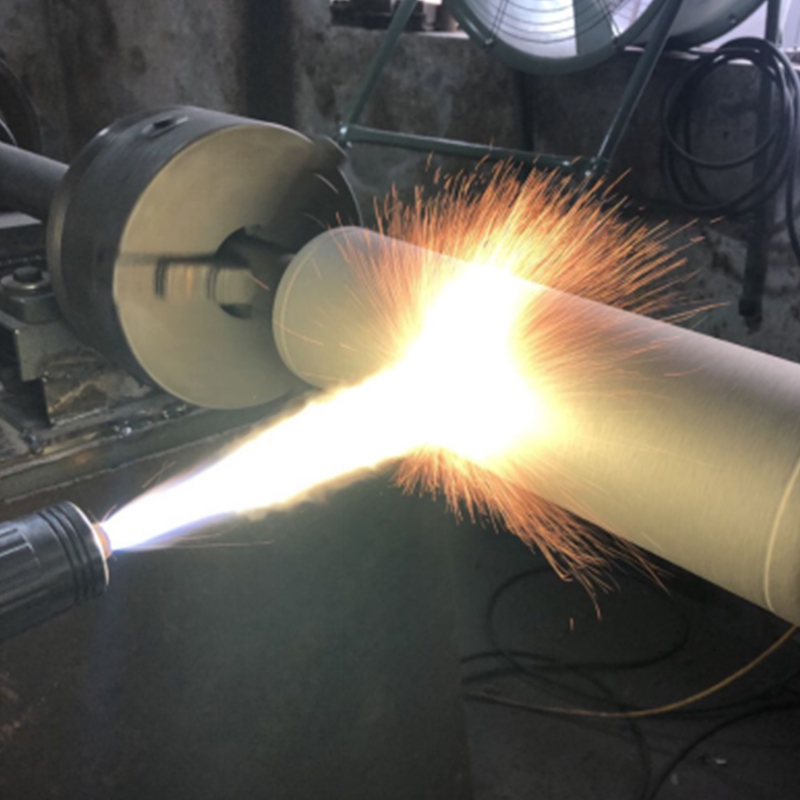

Expert in the field of metal powder manufacturing

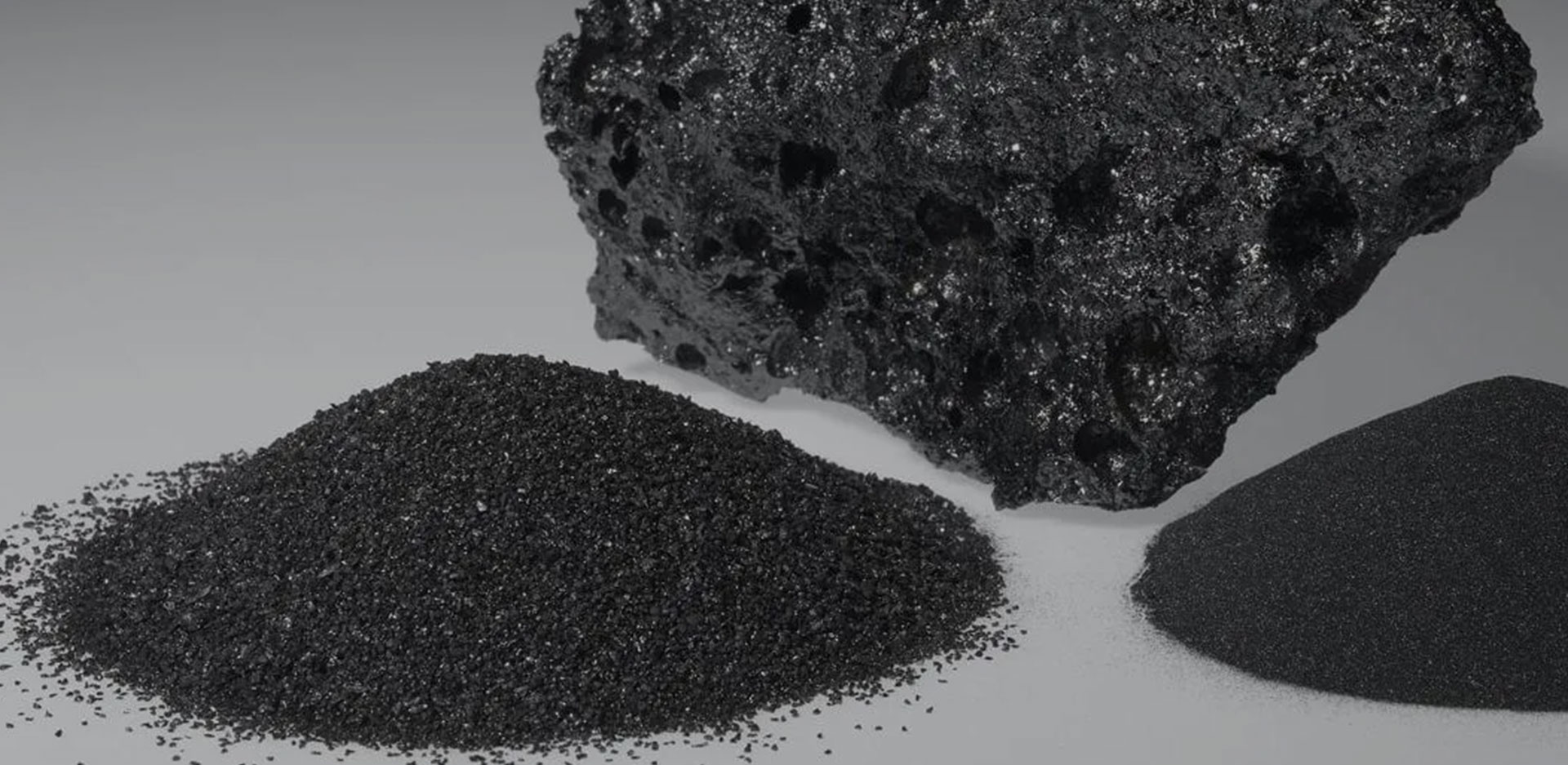

Produces and sells various types of alloy material metal powders that can be applied to various application processes, mainly including nickel-based, cobalt-based, iron-based, copper-based, nickel (cobalt, iron) composite tungsten carbide (material), hydrogen energy catalytic nickel aluminum alloy , chemical fiber filter metal sand series powder

English

English русский

русский عربى

عربى

Prev

Prev

Next

Next